Implant Direct develops a new generation of small-diameter implants for restoring edentulous jaws.

When a fully edentulous patient presents with a narrow ridge, proper implant selection becomes quite critical. The GoDirect™ implant was developed to specifically address the concerns in such cases without compromising long-term clinical success or limiting future treatment options.

The term "mini-implant" has traditionally been reserved for implants with a diameter of 3 mm or less. The most popular diameters are 2.4 mm and 2.8 mm, with ball, ERA, or o-ring abutment platforms for retention of overdentures, and are available from a variety of manufacturers. However, implants less than 3 mm have not received FDA pre-market approval for claims of being a permanent tooth replacement.

A small increase in diameter can offer a permanent solution with significantly more strength. In a recent fracture-strength study, CLINCIANS REPORT compared the one-piece GoDirect implant for use with the GPS™ Overdenture Attachment System to commercially available 2.4-mm and 2.9-mm mini-implants. The 3-mm GoDirect implant was only 3.5% larger in diameter than the 2.9-mm implant, but exhibited 42% greater strength. The GoDirect is also available in 3.7 mm, adding significantly to surface area and strength. The difference in diameter between 2.4 mm and 3 mm is only 0.6 mm, which equals 0.3 mm (0.012") on each side. This is an additional thickness of only three human hairs on each side, thus the 3-mm GoDirect can be placed into a similarly sized osteotomy but provide much greater strength and surface area.

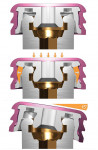

Traditional mini-implants feature a sharp, pointed apex. The GoDirect implant, first introduced in 2008 with a round apex, will soon also be available with a pointed apex. These two designs have slightly different surgical protocols but, because of their evenly tapered bodies, both allow placement in soft bone into an undersized socket using a 2.3-mm/2-mm step drill. The result is gradual expansion of the cortical walls or compressing the soft bone for increased initial stability. In dense bone, the socket is prepared slightly larger using a 2.8-mm/2.3-mm step drill, thereby eliminating the need for a bone tap instrument. The osteotomy can be prepared short of full depth when placing an implant with a pointed apex in soft bone, but attempting to place a small-diameter implant into a socket prepared short of full depth, or in dense bone without establishing adequate diameter and depth to the socket, could potentially cause the implant to fracture.

The GPS Abutment and Attachment System is available for a variety of popular implant platforms in both straight and angled (15° and 30°) options. The GPS metal cap, colorized pink to match the denture base, accepts two types of nylon liners: the GPS External and the new GPS Internal. The GPS External can accommodate up to 40º of relative divergence, although best results are achieved if one does not exceed 30º. It is recommended for use where vertical stress-breaking is not required, such as totally implant-supported overdentures on four implants evenly spread around the arch, or on CAD-milled titanium bars with GPS screw attachments. The new GPS Internal Attachment, designed to provide both vertical and rotational resilience, is recommended for retaining tissue-supported overdentures with two to four anterior implants. The GPS nylon liners rotate together with the metal caps to prevent the possibility of an unhygienic gap present with attachments that allow the nylon to pivot within the metal cap.

Unlike other one-piece implants, the GoDirect can accommodate future treatment options. Internal threading allows attachment of abutment options including a GPS extender and a screw-receiving abutment for retention of a bar or detachable prosthesis. The one-piece GoDirect implant with the GPS Overdenture Attachment provides a cost-effective solution for stabilizing overdentures (Figure 1 and Figure 2).

For more information contact:

Implant Direct

Phone: 888-649-6425

Web: www.implantdirect.com

The preceding material was provided by the manufacturer. The statements and opinions contained therein are solely those of the manufacturer and not of the editors, publisher, or the Editorial Board of Inside Dentistry.