State-of-the-art technology provides better imaging and handling

Andrew Koenigsberg, DDS | Mason Kostinsky

Twenty-five years after the introduction of the first digital radiography system, a majority of dentists are now using digital sensors. Practice management experts consider digital radiography “mission critical,” meaning that practices that do not have this capability will not be able to compete in our rapidly evolving technological world.

The more than 50% of offices that are using digital radiography are certainly on the right track, but is just having a system enough? Few of us are using the same cell phones, computers, TVs, and other devices that we used in 2000. What has changed in digital radiography and how do you decide when it is time to upgrade?

Dentists cite image quality as the most important factor in choosing a digital sensor. “Image quality” is a subjective term, however. An image that looks great to one provider may need contrast, sharpness, or other enhancements to appear as good to another provider.

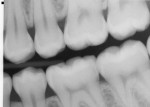

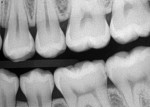

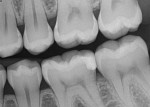

To evaluate image quality, place an image taken with your existing sensor next to an image taken with a new sensor. Be sure that both images are magnified to about the same size. The radiographic images presented here were taken on the same patient, in 2008 with a Schick CDR® (Sirona, www.sirona.com) sensor (Figure 1), in 2012 with a Schick Elite (Sirona) sensor (Figure 2), and in 2013 with a Schick 33 (Sirona) sensor (Figure 3).

Most practitioners would agree that the image in Figure 3 appears sharpest and displays the clearest definition around edges, including pulp space, the dentinoenamel junction, and the margins around the restorations. This clarity could help practitioners more easily identify caries or other hard tissue defects.

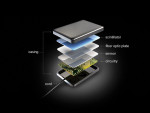

Technical innovations, including increased resolution, improved sensor hardware, better connectivity, and more, have helped the new generation of sensors provide superior image quality (Figure 4).

Image Resolution

Image resolution, which has improved dramatically in recent years, is perhaps the most cited technical factor for improved image clarity. One objective measure of resolution is the number of line pairs that can be seen per millimeter. A line pair is defined as one black and one white line (Figure 5).

As the number of line pairs increases, it becomes harder to distinguish individual lines, until at some point one line pair is indistinguishable from the one next to it. The Schick CDR sensor has a theoretical resolution of 12.5 LP/mm, whereas the Schick 33 sensor has a resolution of 33 LP/mm, helping account for the perceived improvement in image quality.

Sensor Components

Innovations in sensor hardware and manufacturing have also led to improved resolution (Figure 5). The scintillator is the component of the sensor that converts radiation energy to light energy that the sensor can “read.” In many new generation sensors, scintillators are made of cesium iodide, which is more effective at converting radiation into light energy.

Fiber optic plates transmit light energy from the scintillator to the sensor. Newer fiber optic plates are more effective at light transmission, which results in better image quality. Additionally, they reduce the amount of radiation to the sensor, which results in less “noise,” a more diagnostic image, and greater longevity of the sensor.

Sensors that detect light energy to create an image also contain more pixels. More pixels mean better resolution, especially at higher magnification. In addition, new CMOS-APS technology consumes less power than previous CCD sensors.

Software

Traditionally, images were stored and viewed using stand-alone software, usually provided by the sensor manufacturer. This option still exists and uses “bridges” to connect the imaging and practice management software. When a sensor directly integrates with the practice management software, however, there may be a more seamless workflow (ie, fewer clicks), as well as additional features and tools. For this reason, practice management software manufacturers are increasing the number of sensors that will directly integrate.

Recent software advances include caries detection software and preset filtering of images. Logicon caries detector™ software (Carestream Dental, www.carestreamdental.com) analyzes the shades of grey in a radiograph and compares the shades with a built-in library of radiographs in which caries is known to exist. Pre-set filtering in the Schick 33 allows individual dentists in a group practice to set contrast and brightness to their preferences so that each dentist can optimize images to his or her taste.

Connectivity

New generation sensors have more connectivity options and often require fewer components or hardware. Many sensors connect to a “remote box,” which then connects to the USB port on the computer. Some sensors, such as the Dexis Platinum (Dexis, www.dexis.com) and GXS-700™ (Gendex, www.gendex.com), connect directly to a USB port on the computer. Other manufacturers, such as Sirona and Carestream, have released a Wi-Fi module that eliminates any wired connection.

The Planmeca® ProSensor™ (Planmeca, www.planmecausa.com) is able to connect directly to the Planmeca x-ray head, which stores electrical components and is hardwired to the operatory computer. Because the x-ray head is always near the patient when taking a radiograph, this design eliminates the need to run a long cable from the computer to the sensor that is inside the patient’s mouth.

In addition to advances in the technology, the new generation of sensors also offers clinicians upgraded designs to improve the operator and patient experience.

Durability and Reliability

Modern dental practices use sensors every day, and depend on them for consistent, long-lasting performance. Manufacturers have therefore taken measures over the years to enhance the durability and ease-of-use of sensors. In the past, damage to the sensor wire was the most common cause of sensor malfunction. Some manufacturers have made replacing the wire a simple, inexpensive process that can be completed in the dental practice, eliminating the needs for a technician or to send the sensor out for repair.

New generation sensors also have casings and cables that are more durable and can withstand larger impacts from daily use. For example, both the Planmeca ProSensor and RVG System sensors (Carestream) can withstand complete submergence in disinfectant solution. Cables have been made more durable over the years by using materials such as Kevlar® (DuPont, www.dupont.com) and by reinforcing the junction of the cable and the sensor to decrease the likelihood of sensor failure as a result of daily use.

Sensor Design

Improved manufacturing and materials have decreased sensor thickness. Shape modifications such as rounded corners or cut edges may increase patient comfort. Most manufacturers have sensor sizes that are equivalent to film sizes, though not all manufacturers offer all sizes. The Dexis Platinum sensor, for example, is available in only one size. A size 2 sensor, equivalent to size 2 film, will suffice for the majority of imaging needs, though a 0 or 1 may be needed for children or vertical bitewings.

Several support options are typically available, including phone, Internet, and on-site support, from either the manufacturer or distributor. When upgrading or purchasing new sensors, one should be sure that the preferred forms of support are included. In the authors’ opinion, Internet support can save a lot of time, and is a necessity for any computerized, “mission critical” technology. As sensors have become more durable and the market has become more competitive, some manufacturers have extended warranties and service plans that include sensor replacement.

There is no definitive life-span for sensors, but consider other technologies—both inside and outside of the practice setting—that needed replacement before they ceased functioning. At the very least, it is important to be aware that drastic improvements in digital radiography have been made in the past 5 years. Although there is no doubt that replacing sensors (and in some cases associated hardware) is expensive, consider how these improvements can benefit your patients and your practice.

Andrew Koenigsberg, DDS

Partner

Gallery57Dental

Manhattan, New York

Co-Founder

CAD/CAM Excellence

Mason Kostinsky

Chief Operating Officer

Director of Marketing and Business Development

Gallery57Dental

Manhattan, New York

President

Infinity Practice Development

Co-Founder

CAD/CAM Excellence